The MEP National Network’s Supply Chain Optimization and Intelligence Network: Helping Manufacturers Bridge Gaps

National Institute of Standards and Technology

By Joe Edmondson, Nathan Ginty and Mark Schmit

May 31, 2024

When a foreign company wants to manufacture goods in the U.S., it needs new domestic suppliers for just about everything. When such an initiative involves new technology, it creates even more opportunities for a regional ecosystem and associated supply chains.

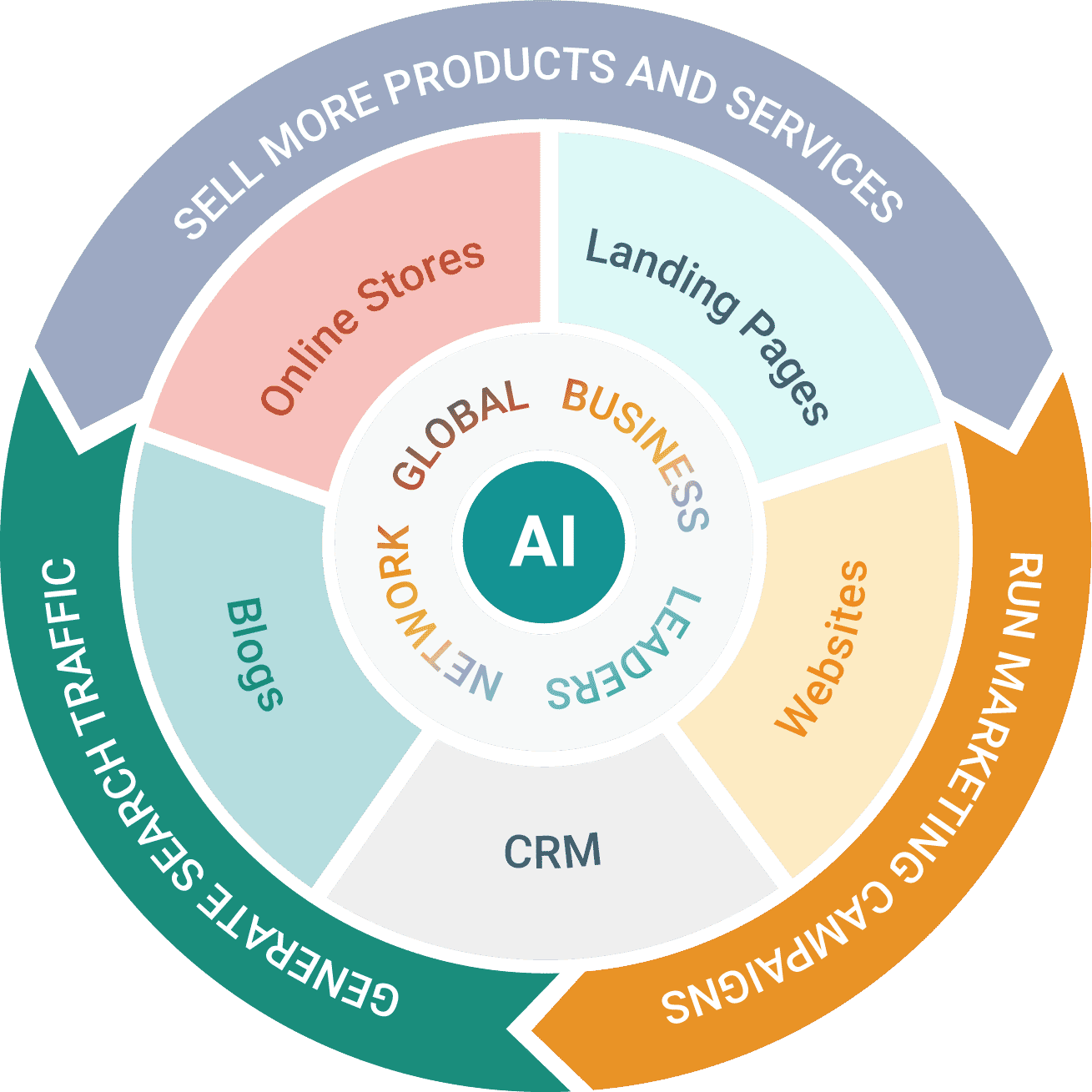

Topsoe is a Danish energy company that is slated to build a $400 million Electrolyzer facility in Chesterfield, Virginia. Their technology utilizes renewable electricity from sources like solar and wind power to split water molecules into hydrogen and oxygen. This creates green hydrogen, a clean and carbon-neutral fuel. It is designed for industrial-scale production, making it capable of meeting the growing demand for clean hydrogen and its applications. This investment in American manufacturing coincided with the June 2023 launch of the National Institute of Standards and Technology (NIST) Manufacturing Extension Partnership (MEP) National Network’s Supply Chain Optimization and Intelligence Network (SCOIN), a two-year pilot program to kick-start supply chain efforts across the country. Authorized by the CHIPS and Science Act of 2022, NIST MEP awarded a total of $20 million for the SCOIN to MEP Centers in each state and Puerto Rico. Through this groundbreaking initiative, MEP Centers are expanding the Network’s scope from working primarily with individual companies to include a more comprehensive approach to manufacturing supply chains.

Many supplier scouting requests are for specific components or are limited in scope. But the Topsoe initiative is so large that it has turned out to be an ideal scenario for implementing SCOIN at scale. It closely aligns with the major SCOIN goals to:

Map the capabilities and interconnections within manufacturing supply chains.

Scale up and enhance the impact of supplier scouting services, which help organizations source domestic products and expand their capabilities.

Enhance resilience and reduce supply chain vulnerabilities for manufacturers.

Strengthen and revitalize regional manufacturing ecosystems.

Connect original equipment manufacturers (OEMs) with small and medium-sized manufacturers (SMMs).

Topsoe initiative offers big opportunity for green energy supply chain

In June 2023, Joe Edmondson of the Oklahoma Manufacturing Alliance met an official from the Danish consulate at a manufacturing event. The Danish representative was looking to connect an unnamed company, which turned out to be Topsoe, with suppliers in the U.S. During their discussion, Mr. Edmondson touted the MEP National Network’s supply chain development expertise.

It turns out that Topsoe’s interest in the U.S. coincided with the Biden Administration incentivizing European investments in U.S. manufacturing. The company approached a U.S. government program led by the U.S. Department of Commerce that focuses on facilitating job-creating business investment in the United States and raising awareness of the critical role that economic development plays in the U.S. economy. The program made connections with appropriate stakeholders, such as state governments, economic development agencies, and the MEP National Network. This alignment of government agencies helped Topsoe quickly and effectively get the wheels in motion to make this investment.

By September 2023, Topsoe had identified itself as the company interested in building a facility, and the Oklahoma Manufacturing Alliance and TMAC, the Texas MEP Center, began the initial supplier scouting work.

Mapping capabilities and casting a wide net for prospective suppliers

Topsoe is investing in manufacturing its new solid oxide electrolysis cells (SOEC), so there are no turnkey products or existing supply chains. Mr. Edmondson, the MEP lead on the initiative, started by “reverse engineering” the technology to understand what capabilities were needed to build and operate the cells. The initial nationwide scouting focused on manufacturers’ capabilities as opposed to turnkey components as many companies might be able to pivot to produce parts or components.

Given the lack of specifics at that time about the location of a new facility, early communications about the opportunity were sent to all 51 local MEP Centers through the supplier scouting service. Topsoe was provided with a pool of 12,000 capable suppliers nationwide, which they narrowed to 300 prospective companies from 38 states, using criteria such as capacity, specific capabilities, and certifications.

Edmondson then submitted an application for each of the 300 prospective supplier companies. If the company was selected for the next phase, Edmondson let the company know and helped it understand the opportunity. This way, the prospective supplier began this process with a small win: “A big company is interested in learning more about your capabilities!”

Topsoe provided Edmondson with its core supplier expectations, which he shared with local MEP Centers. It also positioned local MEP Centers to help companies become supplier-ready by closing gaps in capabilities or certification. In this way, supplier scouting plays to the holistic strengths of the MEP National Network in bridging supply chain gaps.

Topsoe doing site visits as the MEP National Network helps bridge gaps

Topsoe selected 35 companies from 14 states to apply for the request for quotation (RFQ) stage. Edmondson alerted them to the opportunity and invited them to a Topsoe summit in Houston to learn more. All 35 attended, 31 in person and four virtually.

Amazingly, all 35 prospective companies were advanced to the RFQ stage because of the significant vetting that took place with the MEP National Network’s expertise and information gathering process. That expertise and access are at the heart of the MEP National Network’s value to a company like Topsoe.

Topsoe is in the process of conducting site visits to each of the 35 suppliers in coordination with local MEP Center staff to see operations and learn more about capabilities, opportunities, and constraints. The MEP representatives are looking at supplier readiness (people, certifications, automation, etc.) and evaluating what services they can offer these suppliers to fill gaps and strengthen their value as a supplier, now and in the future.

Source: https://www.nist.gov/blogs/manufacturing-innovation-blog/mep-national-networks-supply-chain-optimization-and-intelligence